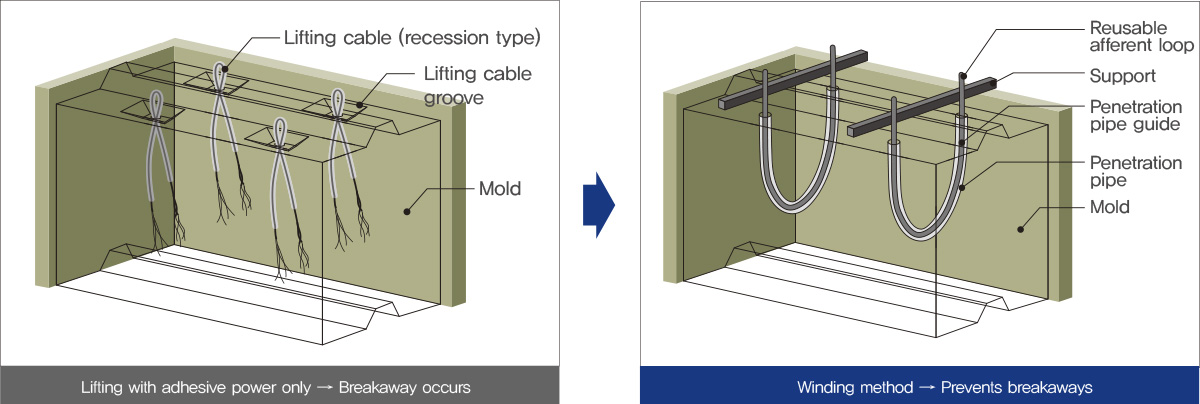

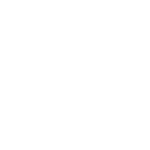

01 Structural Stability

- • Unlike the existing method of lifting through adhesive force, a winding method is used

- • Use of wire ropes without ends - About three times more stable

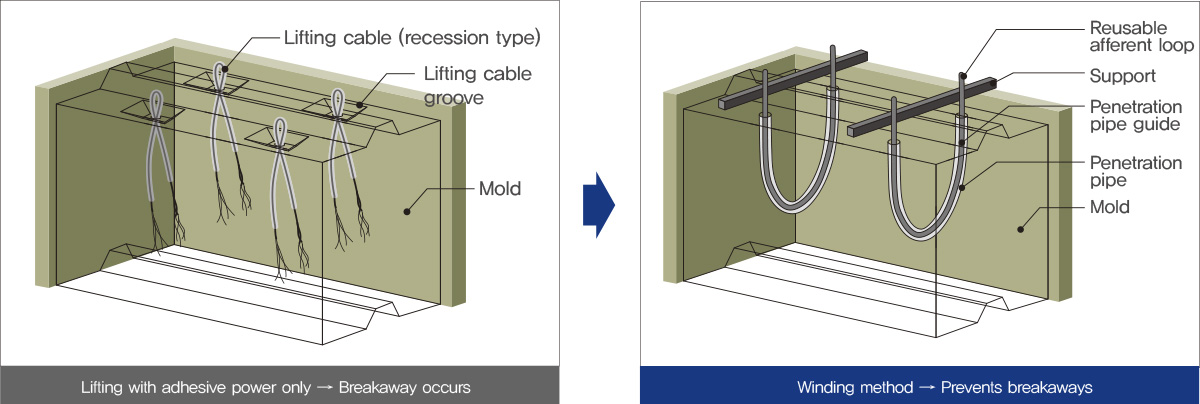

3D numerical analysis (new method)

A. Analysis result

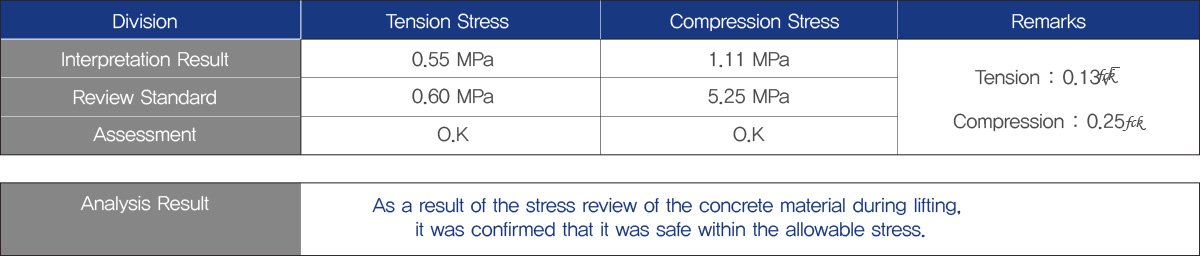

B. Stress Review

02 Workability

- • No need for heavy wire rope cutting and processing

- • No need to install a lifting cable box

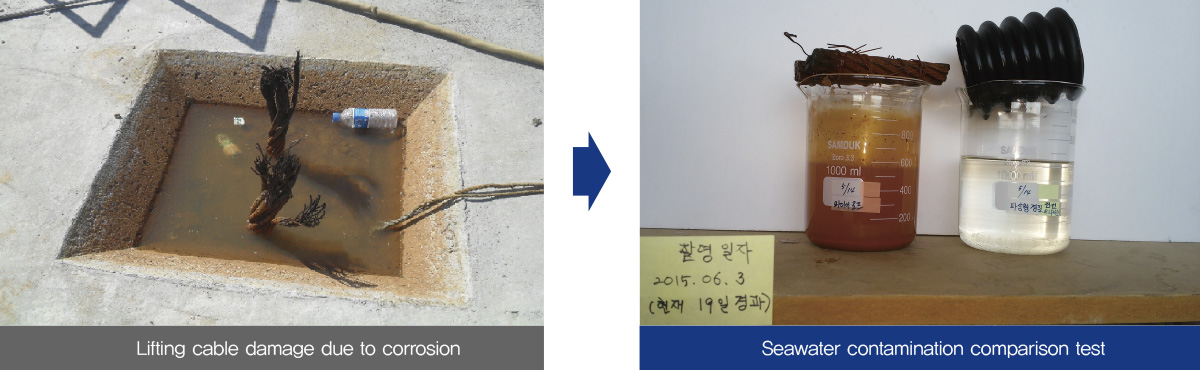

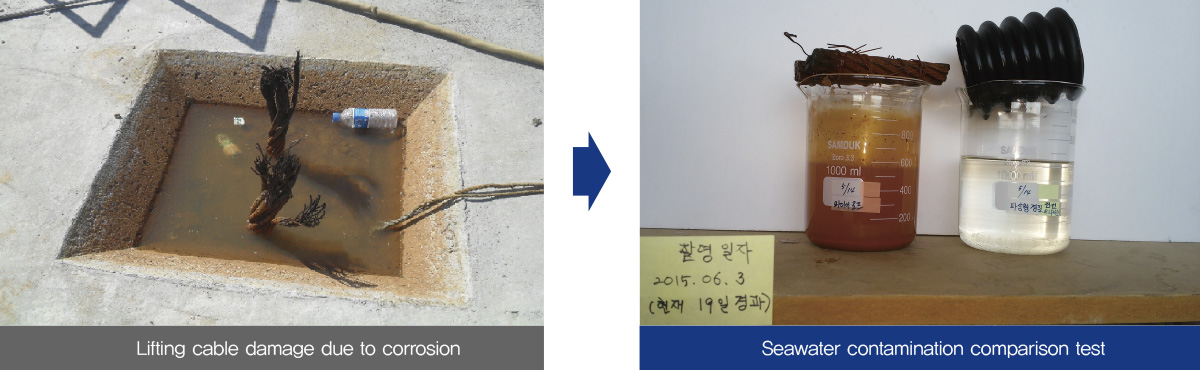

03 Quality

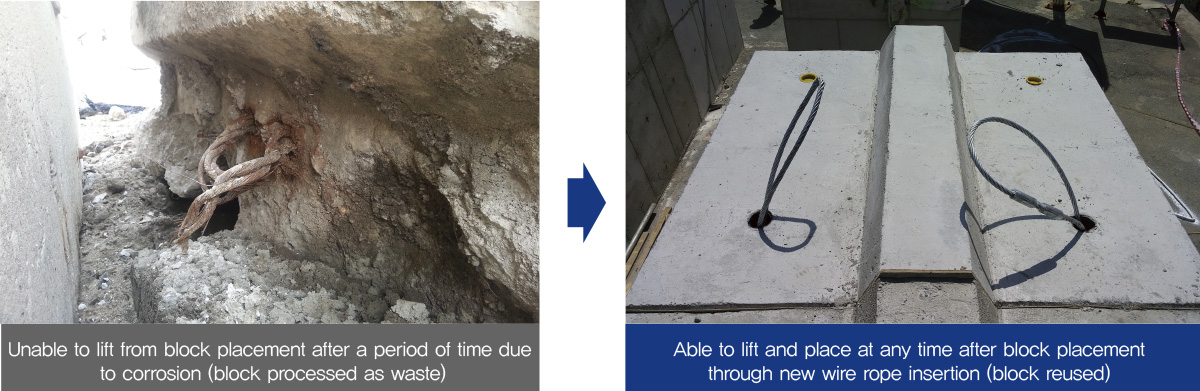

- • Volume expansion due to wire rope corrosion - Causes block cracks

- • No risk of corrosion since there is no wire rope

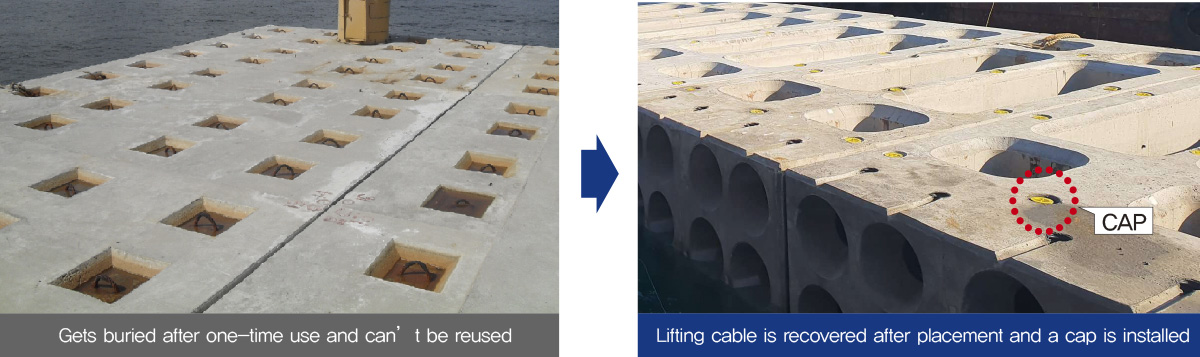

04 Eco Design

- • When lifting, rusty water continues to occur after one use - Causes seawater contamination

- • No rust because there is no iron component - Prevention of seawater pollution

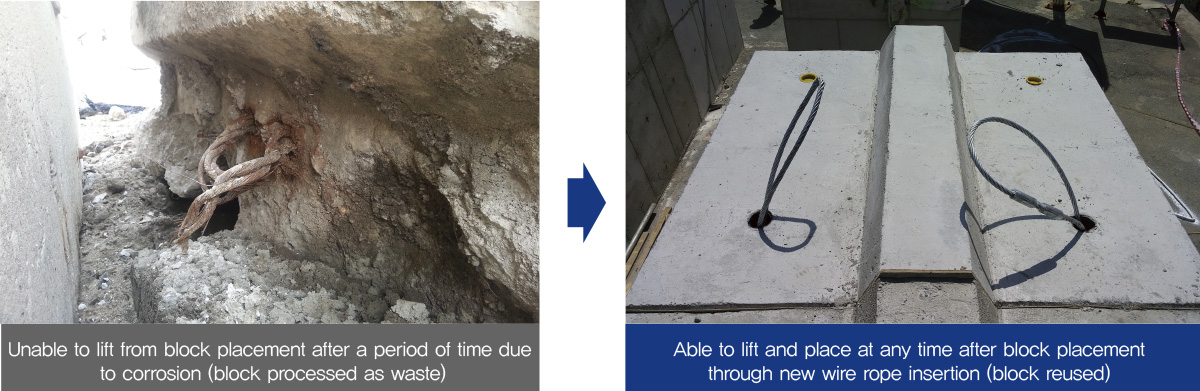

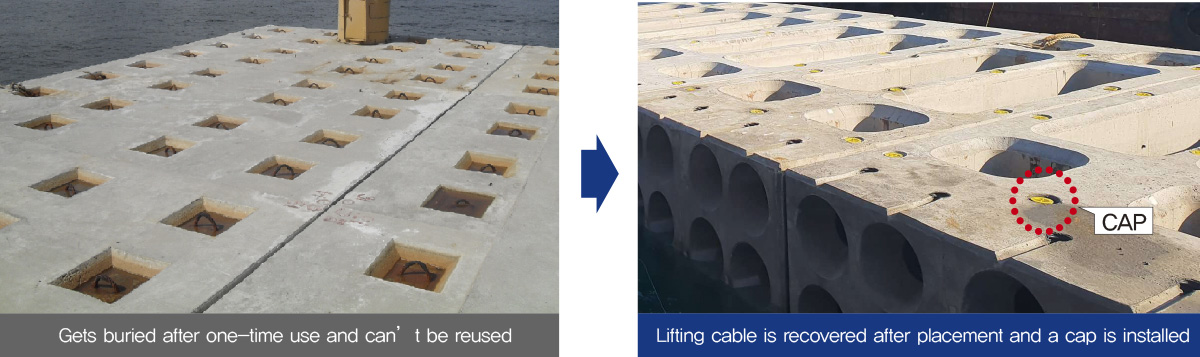

05 Economics

- • Increase in construction cost because the wire rope lifting cable can’t be used after one-time placement

- • The lifting cable can be recovered after placement and re-used more than 100 times for block placement

06 Maintainability

- • When the block is lifted again after a certain period of time, it is possible to re-lift by inserting a wire rope through the penetration pipe.