YUJOO WAVE

01 Operation Principle

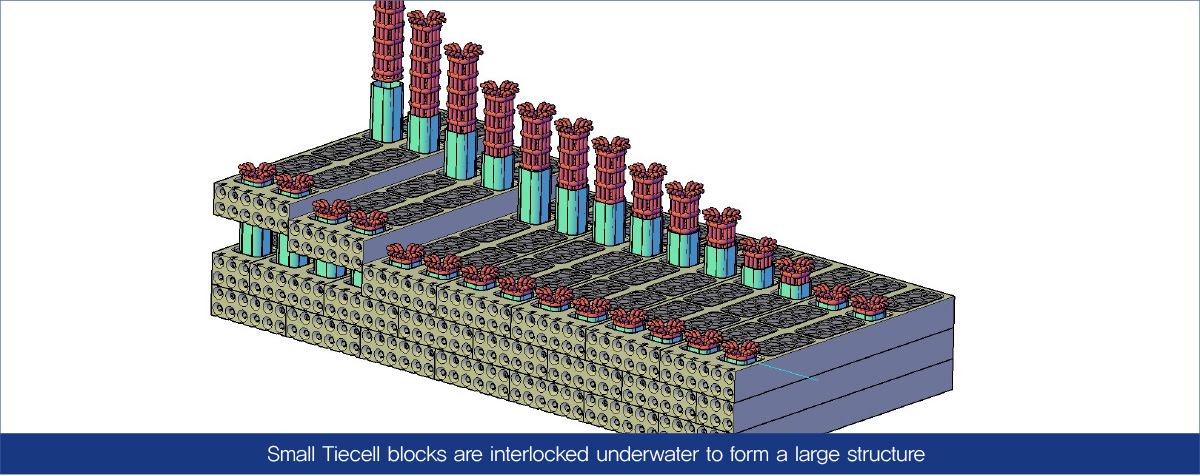

- • Integration of the structure by interlocking separated blocks from the top, bottom, left and right underwater

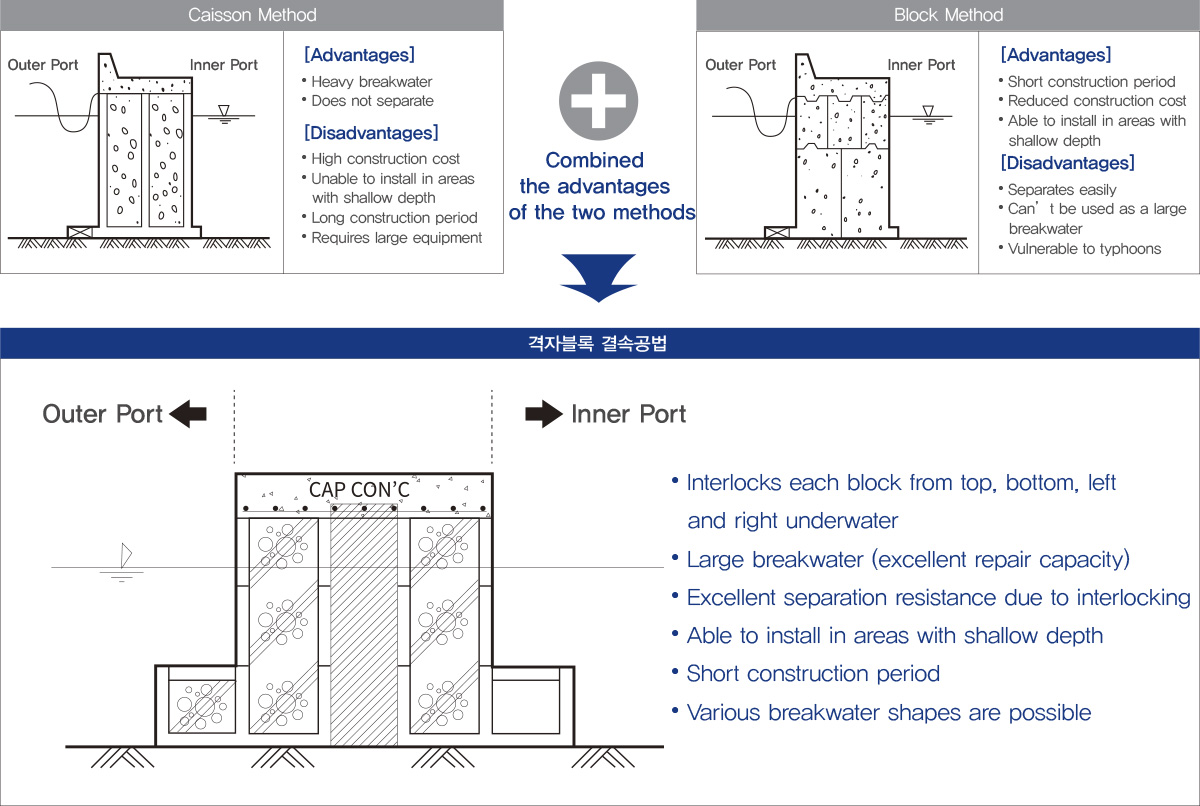

- • The caisson method provides excellent stability, but because it is a large and heavy object, the construction cost increases for manufacturing, lifting and mounting

- • Source technology that can be applied to all marine structures from small fishing ports to large container piers

Underwater block interlock technology

02 Improvement of Efficiency

- • Unlike conventional breakwaters, since each block is interlocked from the top, bottom, left and right sides underwater due to the interlock structure and ensures reliable stability against waves, it enables the implementation of various breakwater shapes.

- • There may be minor errors in the production of blocks, and these may occur because they are mounted in water. The solutions to these errors are as follows

- - The rebar mesh is made 30% smaller than the original lattice holes

- - When designing the interlocking pipes, the diameter is designed to be 30% larger than the size in the structural review so that there won’t be structural stability problems even if a construction error occurs.

- - As shown in the figure, even if an allowable error occurs in the production and installation of the blocks, since the square rebar net is 30% smaller than the lattice holes, there isn’t a problem with embedding.

- - The seawater barrier is installed in close contact with the lattice hole side by lateral pressure to bind the blocks.

Flow Chart of Tiecell Blocks

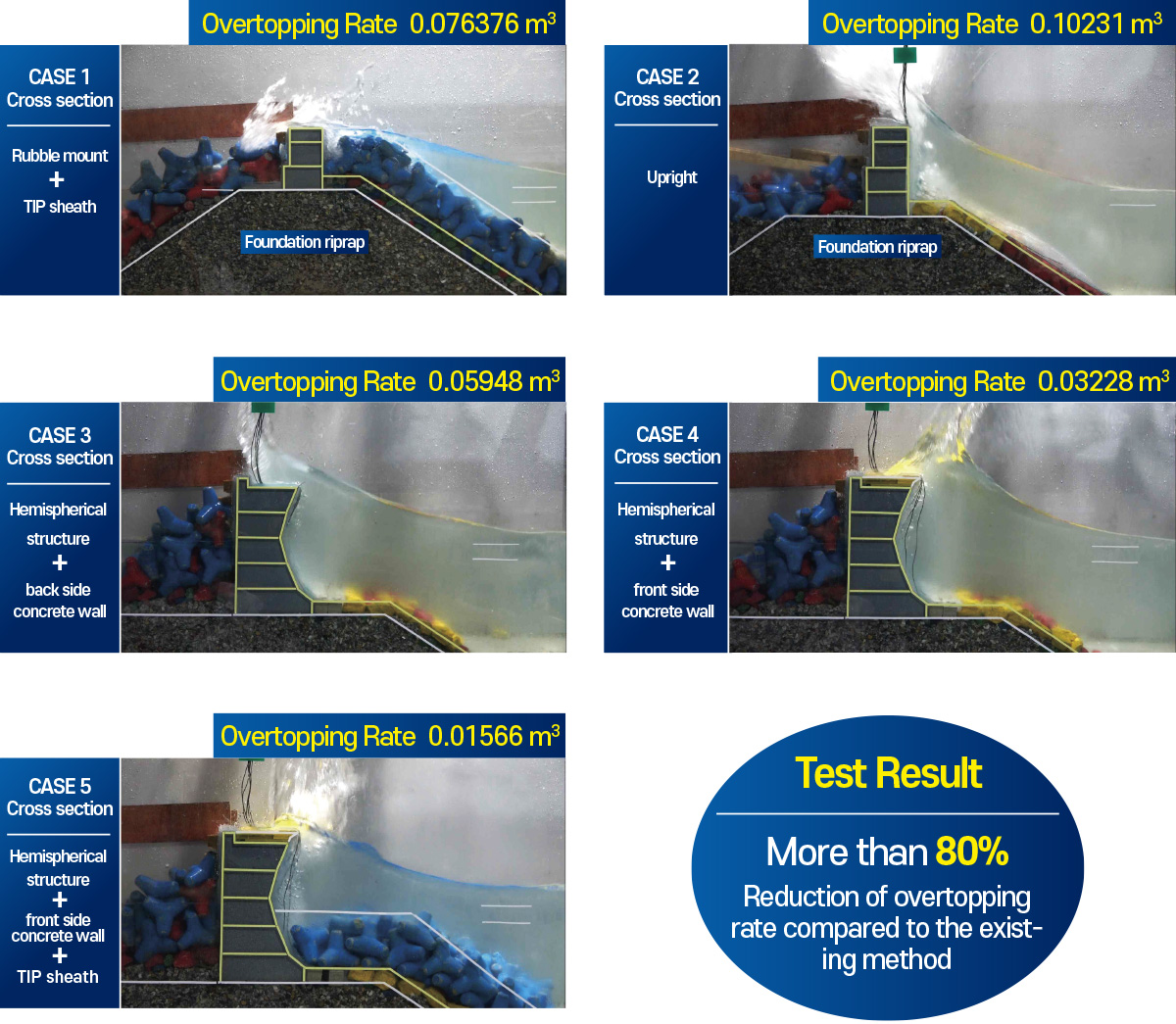

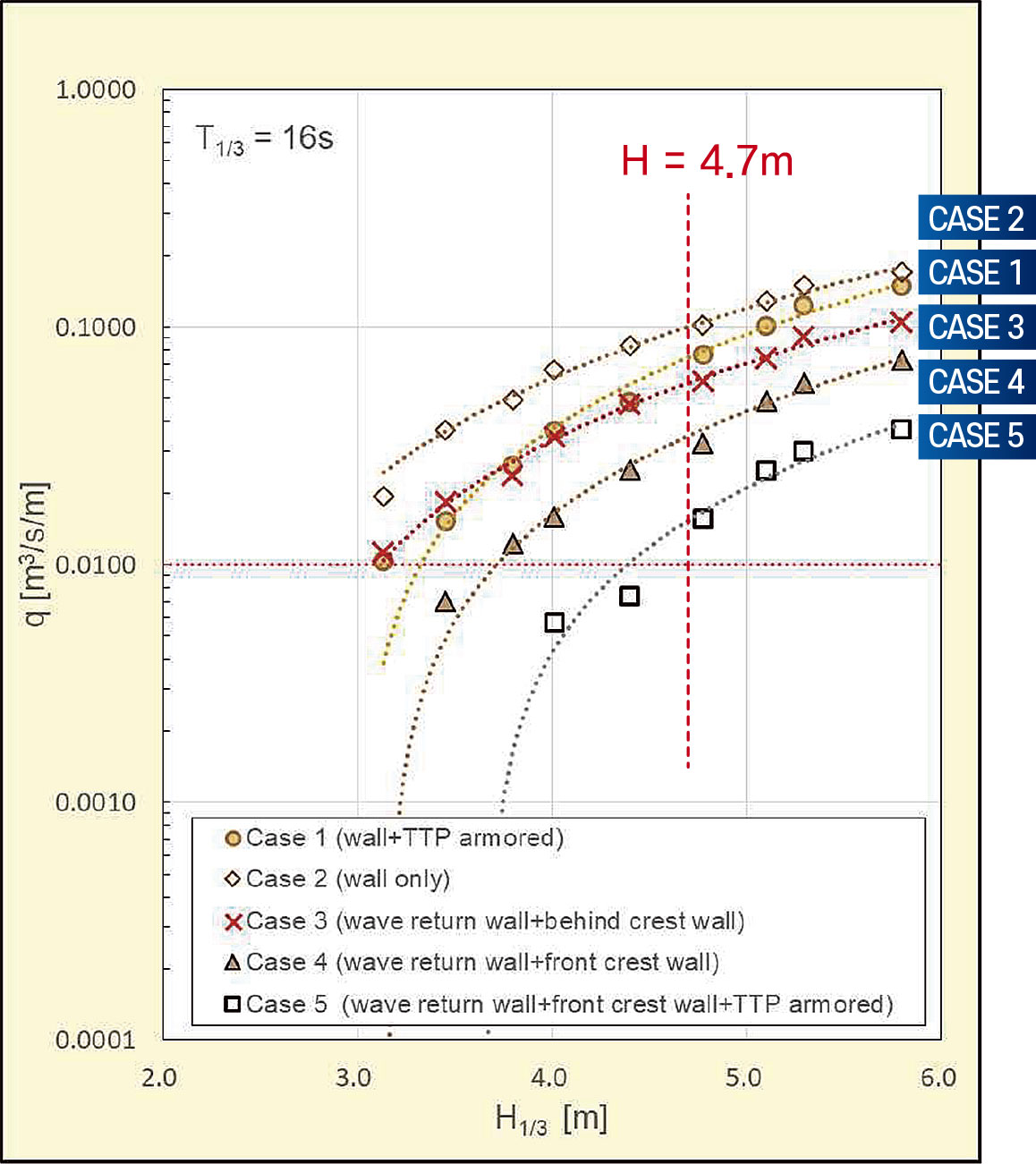

03 Hemispherical Tiecell Returning-waves Block Overtopping Rate Hydraulic Characteristics Test (Wave Height 4.7 m, Cycle 16 sec)

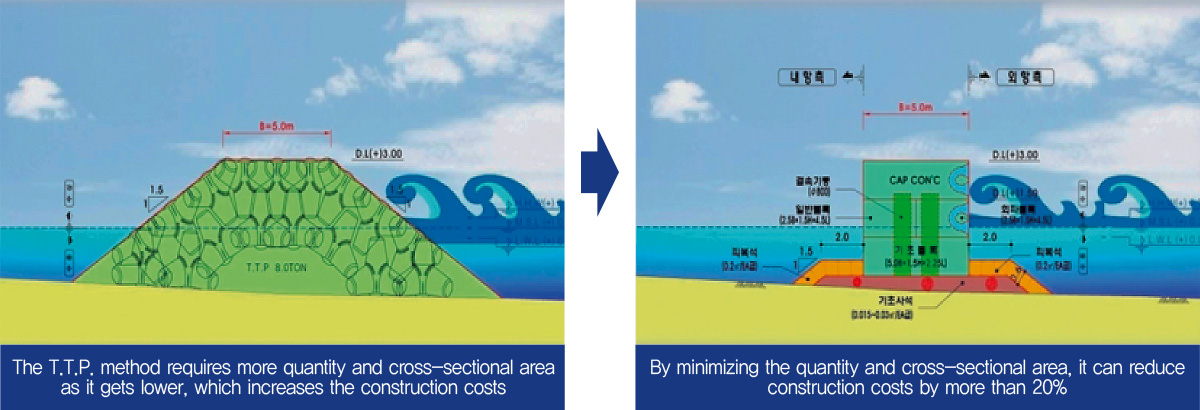

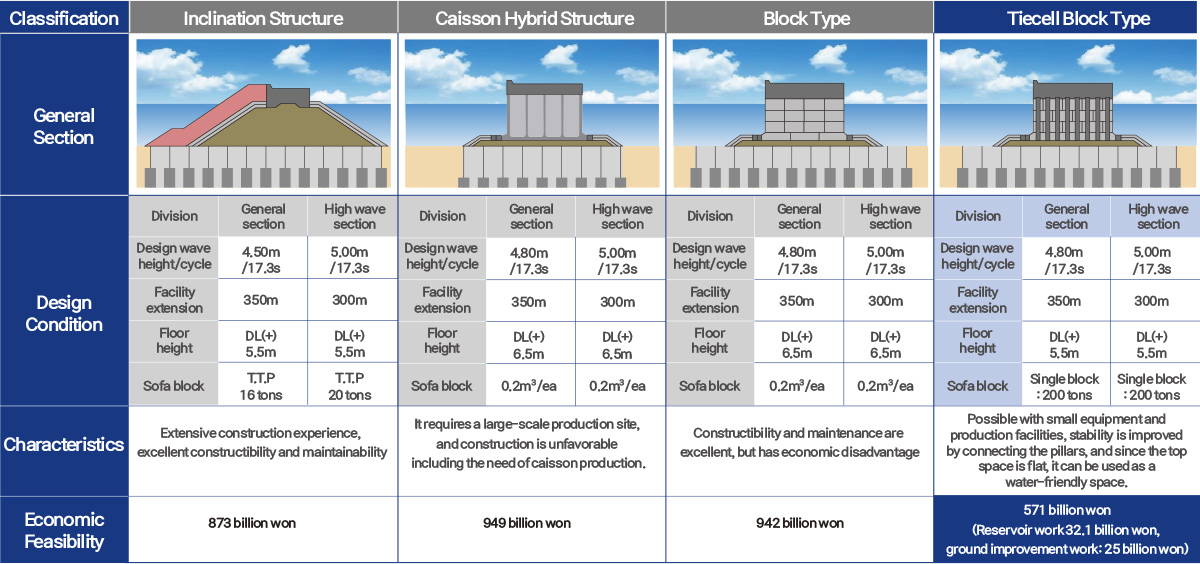

04 Economics

- • Economical due to the minimization of quantity and installation cross section compared to T.T.P.

- • By manufacturing and placing small blocks on the ground and interlocking them underwater, it has the stability of the caisson method as well as economic feasibility.

Economic feasibility is secured through the minimization of cross sections and quantity

Caisson method application by manufacturing small blocks and then interlocking them underwater

Efficiency of Tiecell Blocks

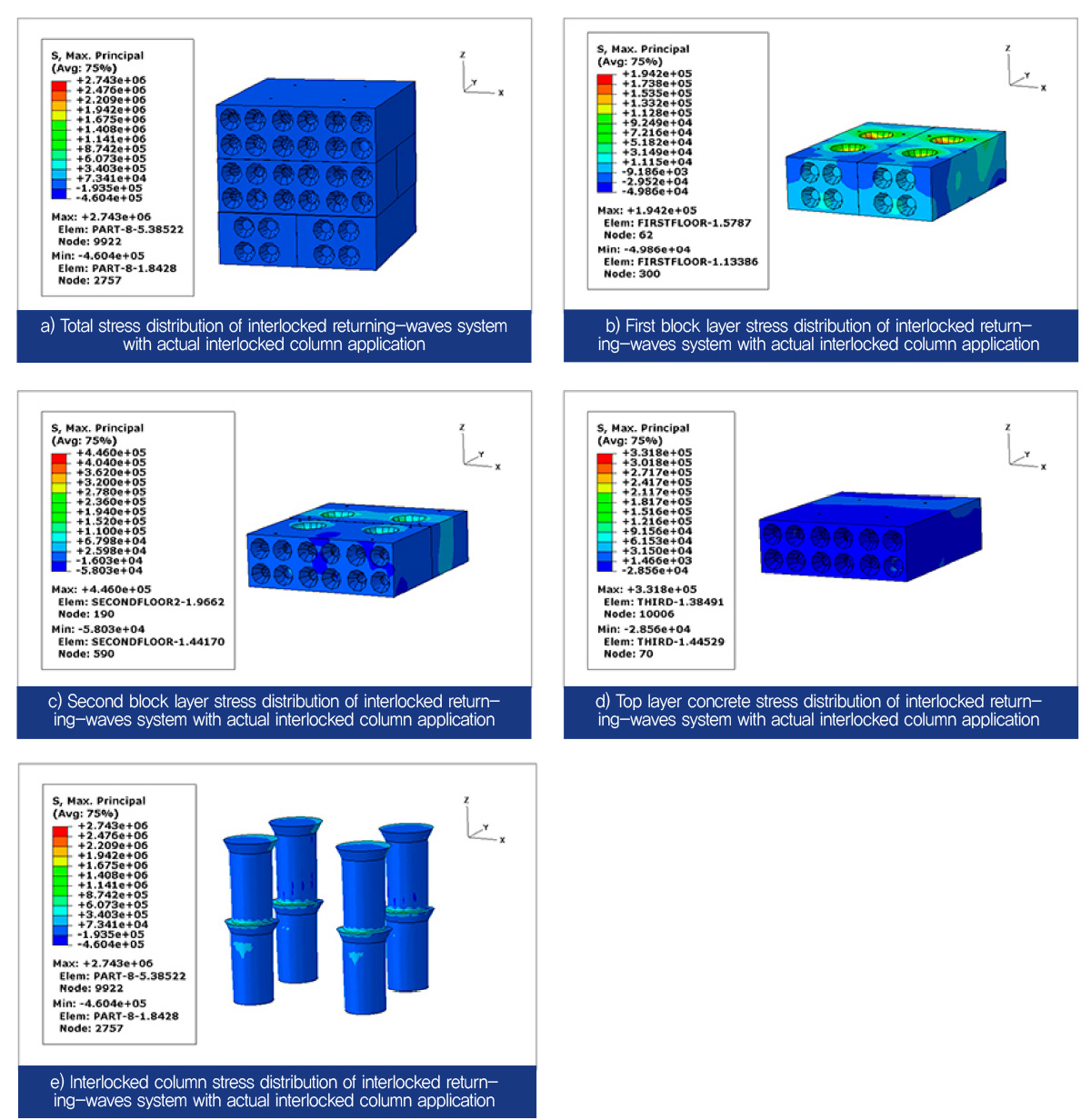

05 Structural Stability

06 Paradigm change

Change in harbor structure construction methods

Construction Method Comparison by Economic Feasibility

07 Utilization

- • Widely used from small ports to large container wharf construction

- • The blocks can be interlocked underwater, so they can be installed with small equipment. They are also stable against large waves such as typhoons.

- • It is the most economical technology for reinforcing structures adjacent to the shore.

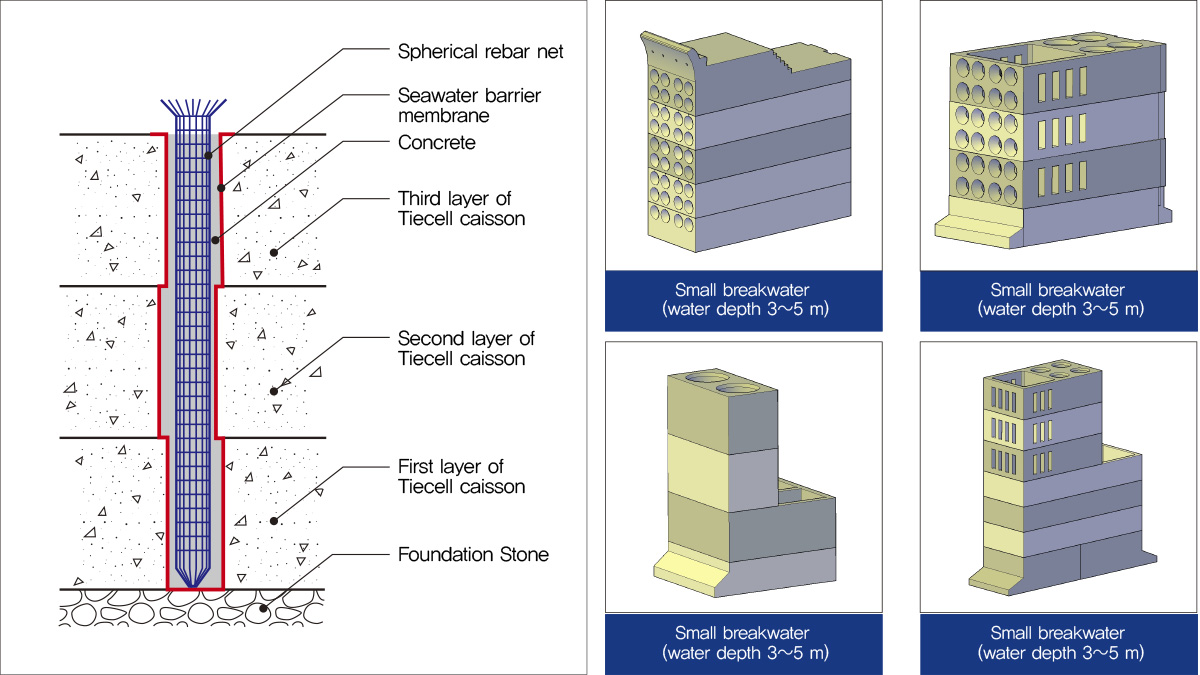

08 Design

- • Can solve the problem of stability with interlocked columns

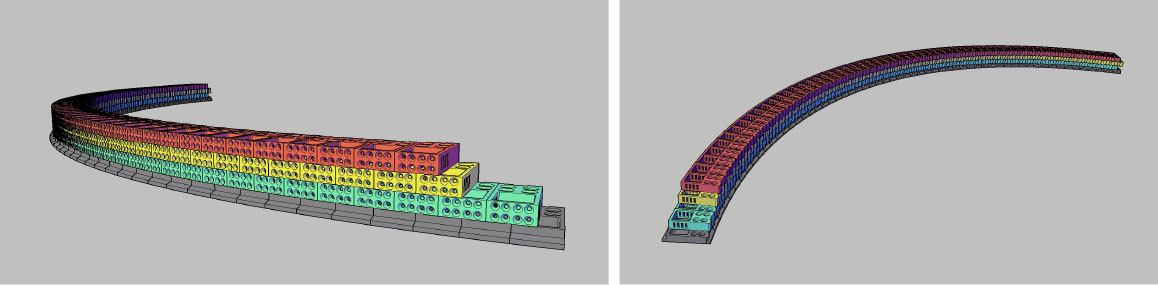

- • Various shapes can be formed with the interlocking pattern of stacking the blocks.

- • Unique marine spaces can be created in each harbors that had T.T.P.s and be turned into a resource for tourism

Circular Breakwater

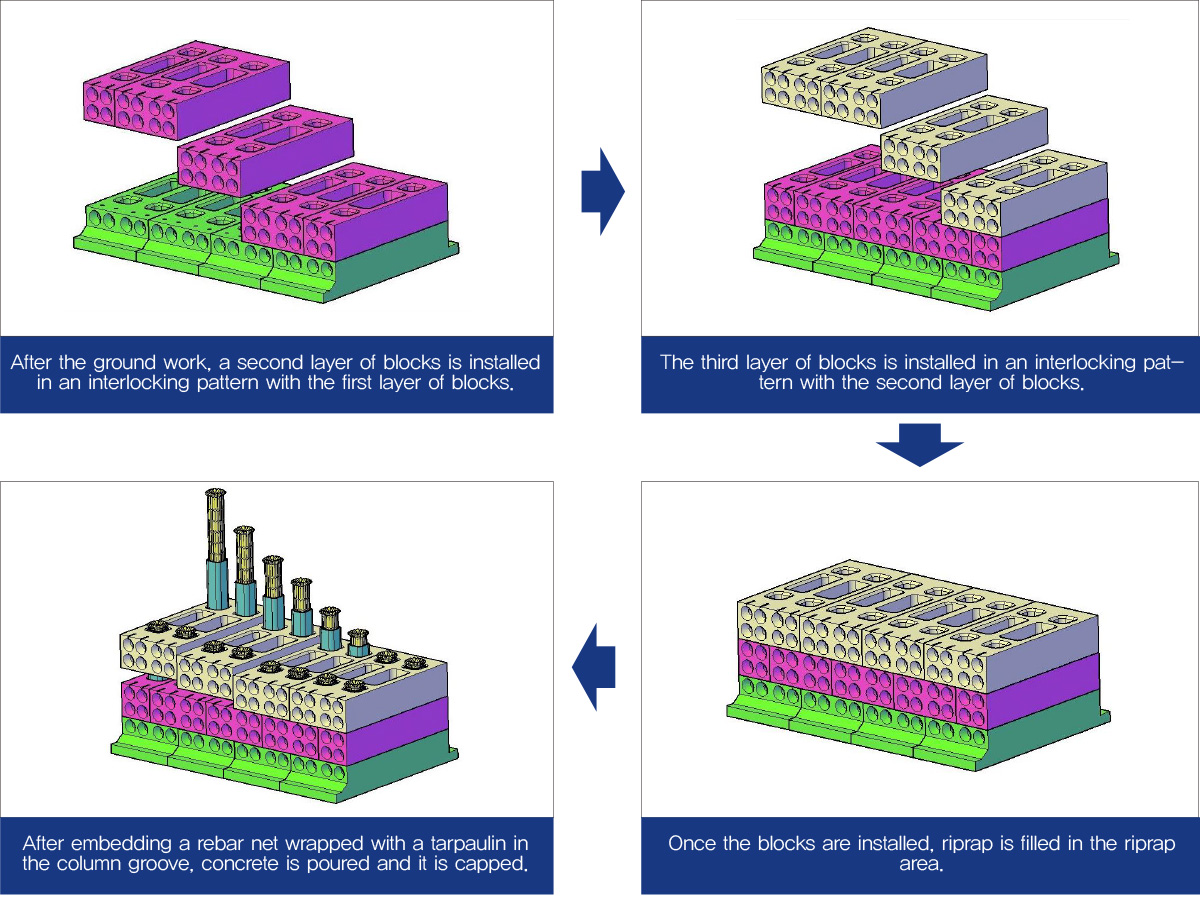

09 Latticed Block Construction Process

- • Lightweight Tiecell blocks are made on land

- • The Tiecell blocks are installed underwater.

- • Riprap is filled in the riprap area of the blocks to secure weight.

- • Rebar net covered with waterproof membranes is embedded in the column holes of the blocks.

- • Concrete is poured into the column holes.

- • Reinforcing bars are placed in the upper areas of the rebar nets of each column, and cap concrete is laid.